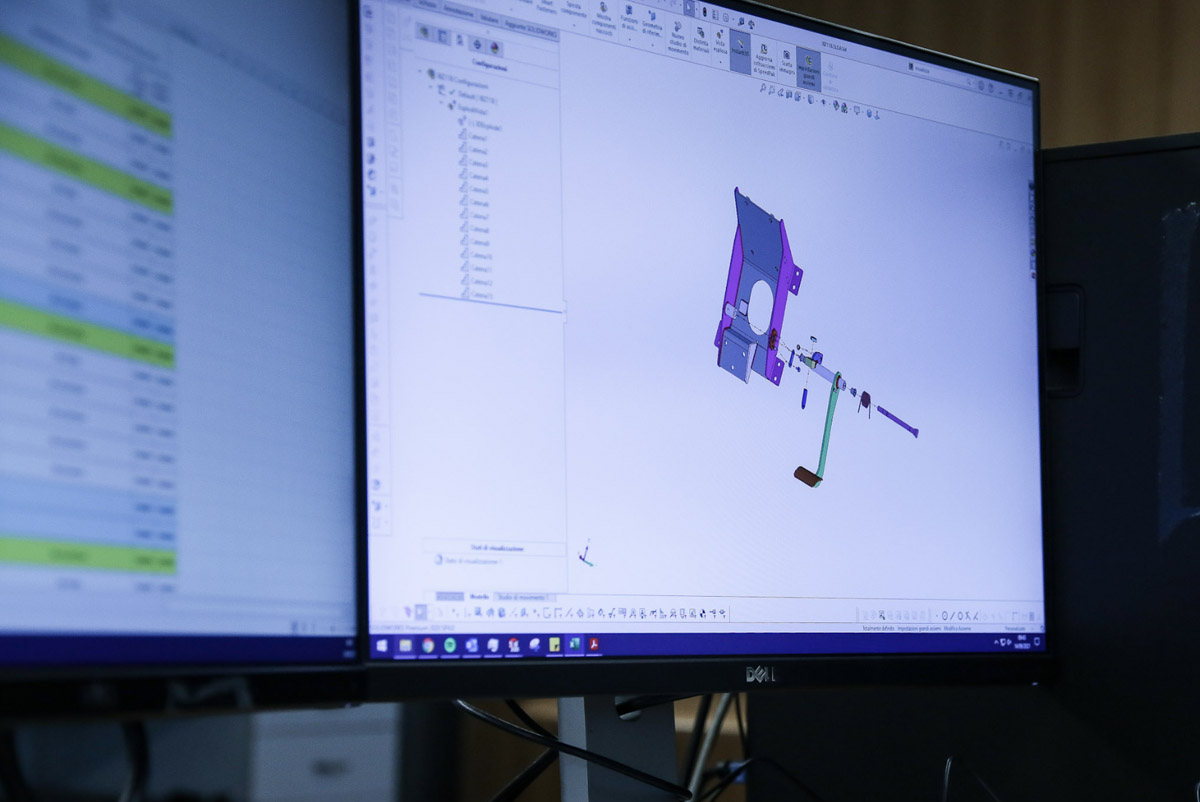

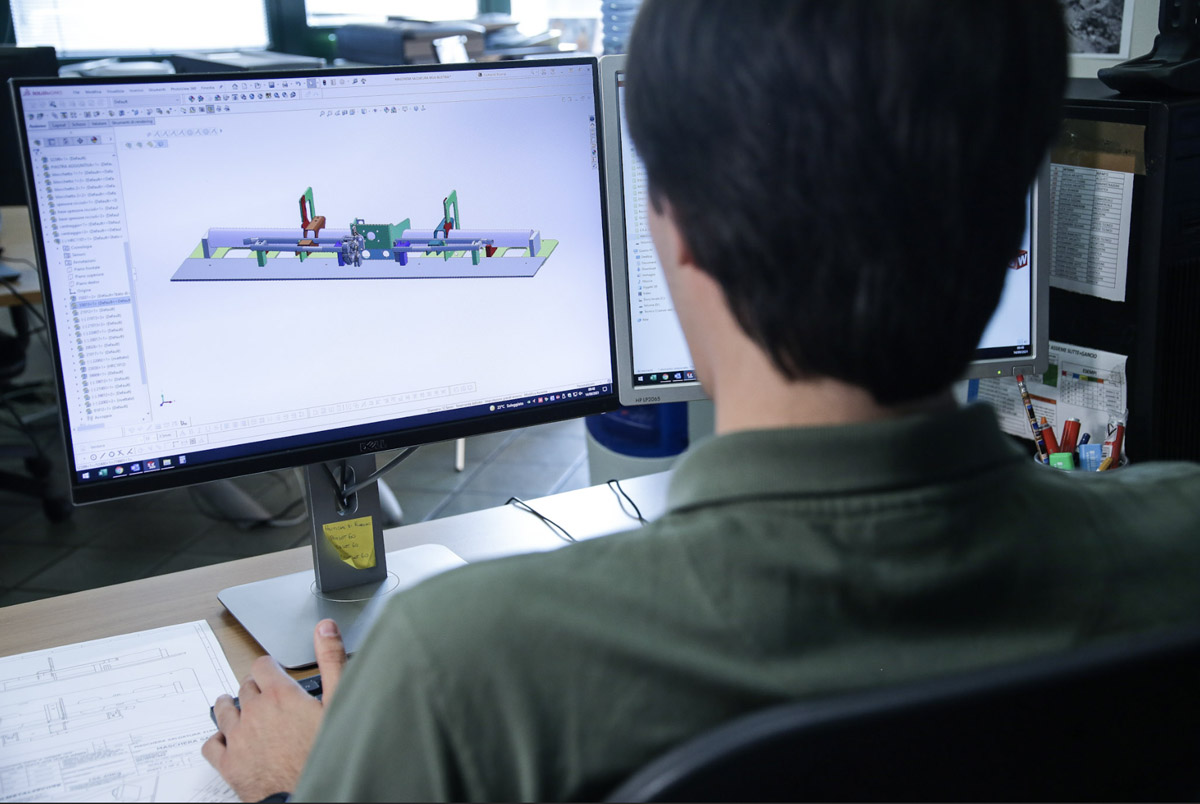

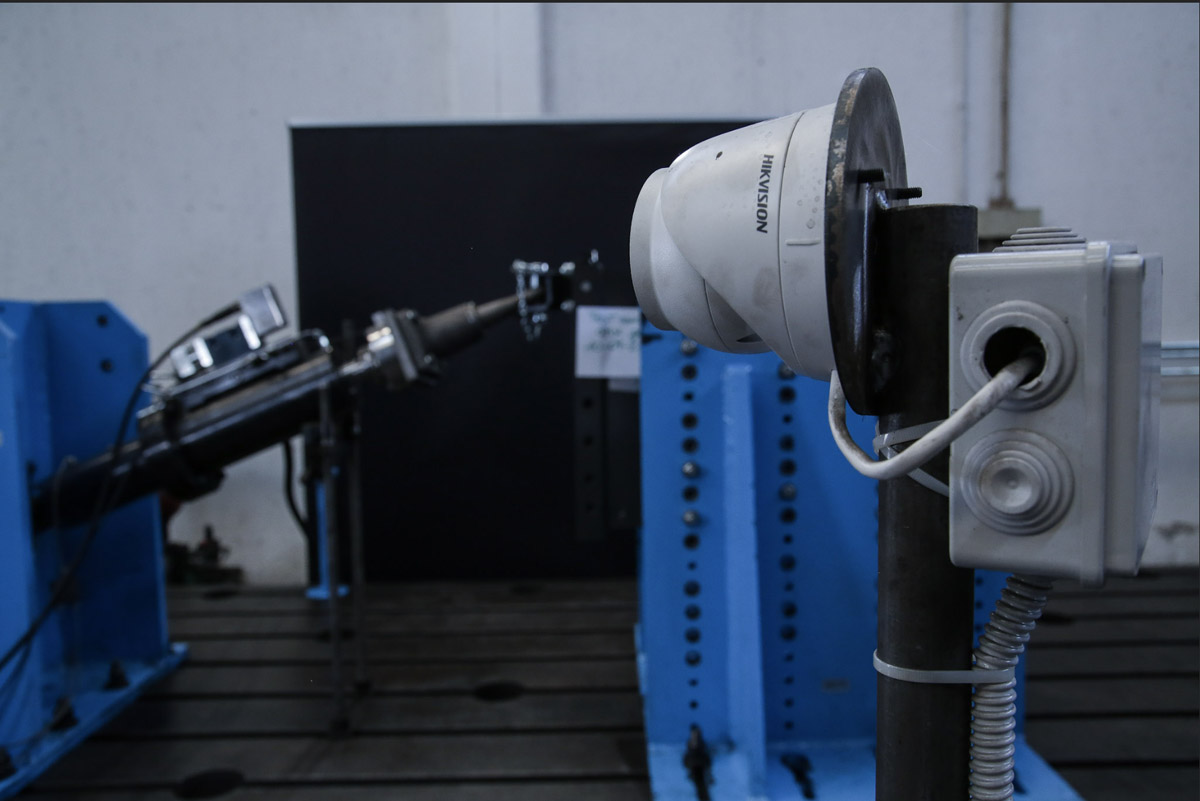

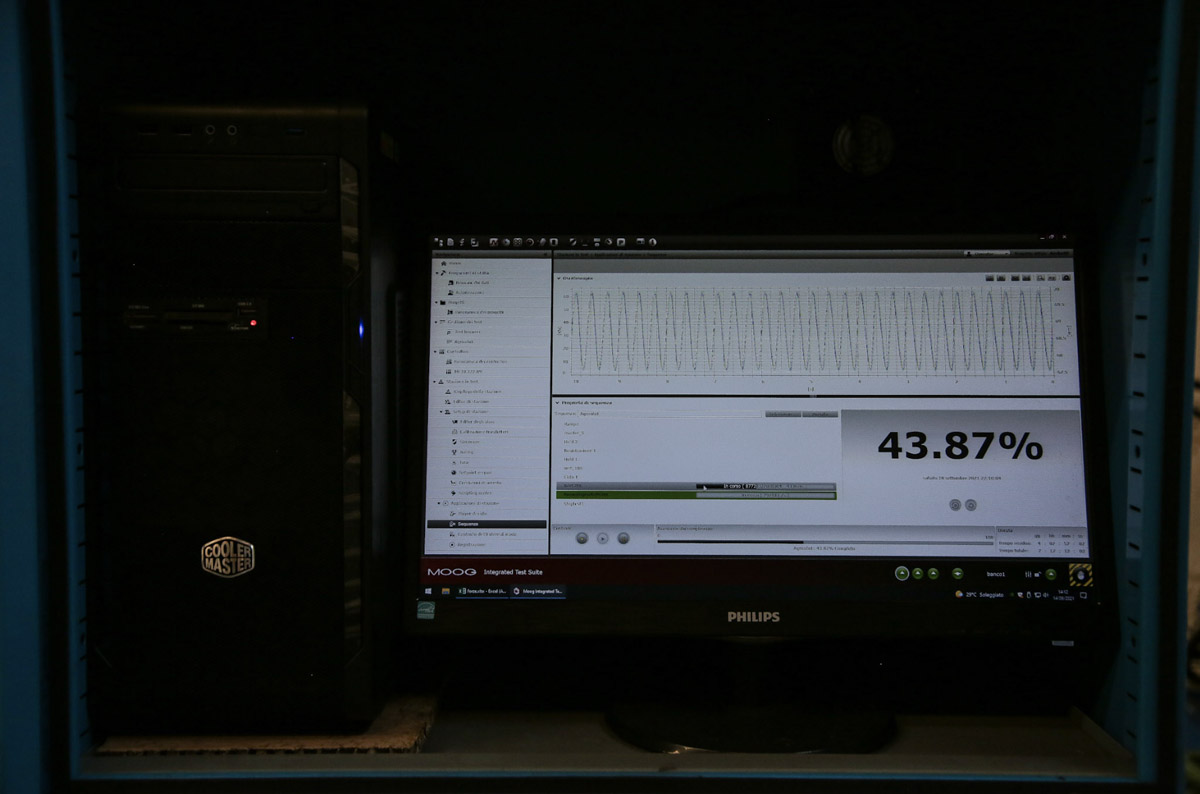

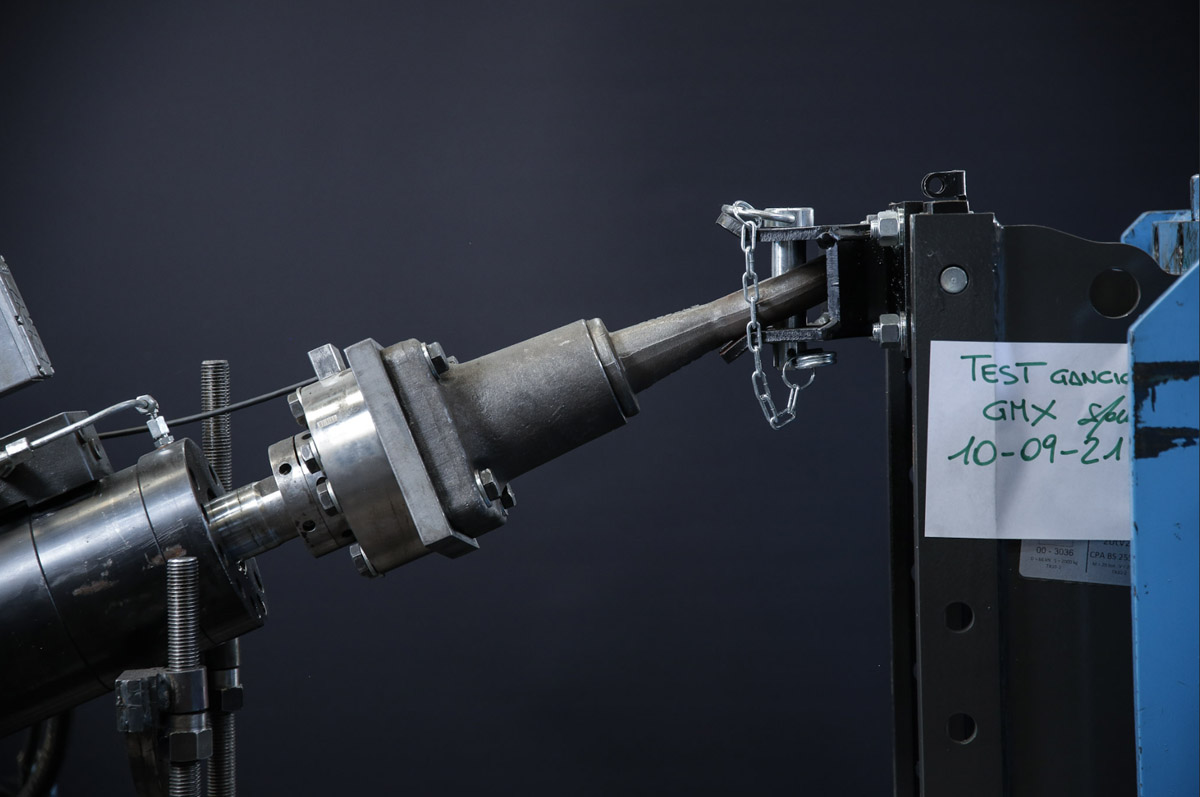

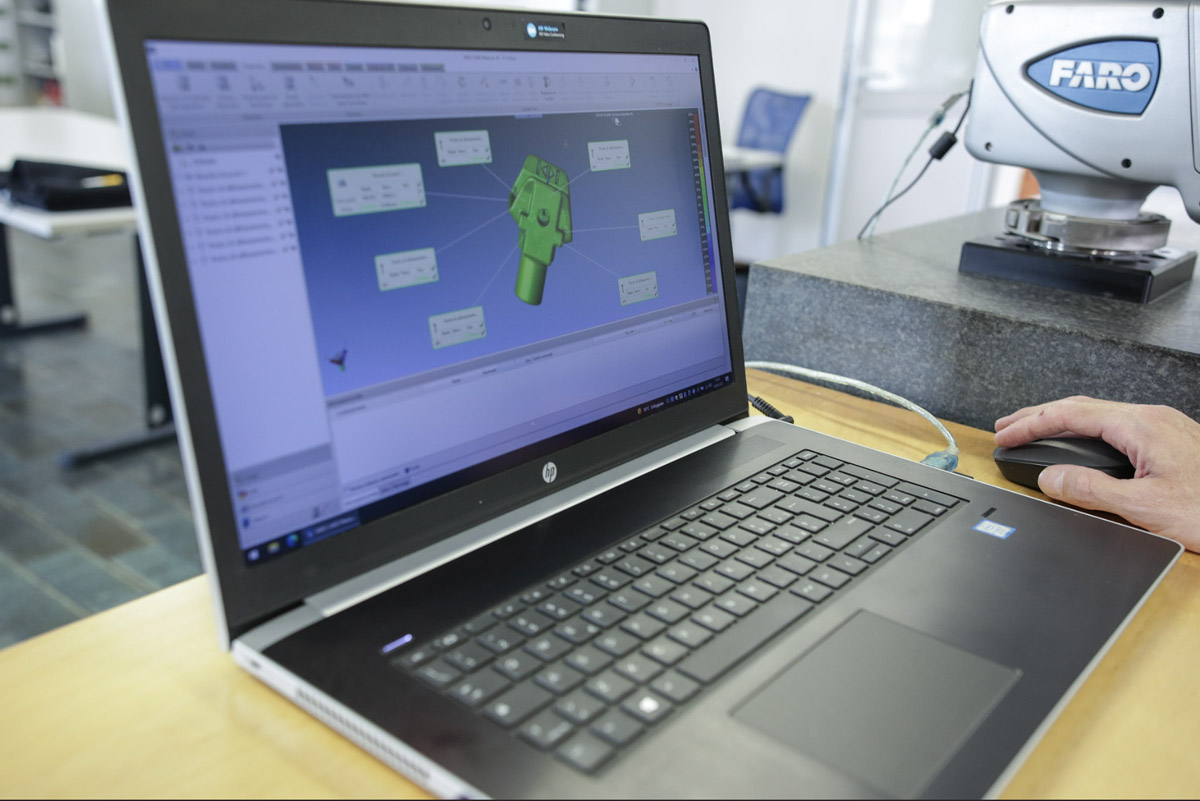

Starting from the specific technical needs and the product mission defined by the Customer, Metalsecure makes specific design and industrialization skills available through the related prototyping and validation phases. Customers benefit from it in terms of constant quality and traceability of processes, both in mass production and in the manufacturing of limited lots.

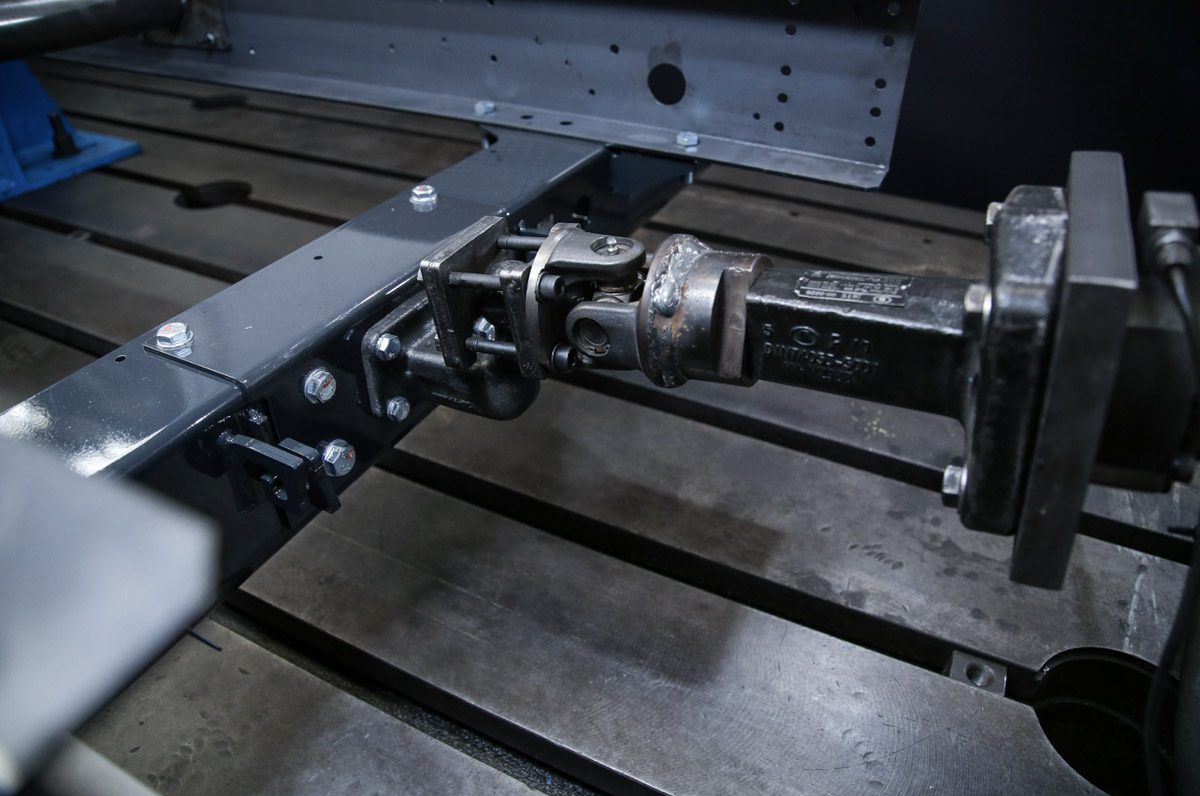

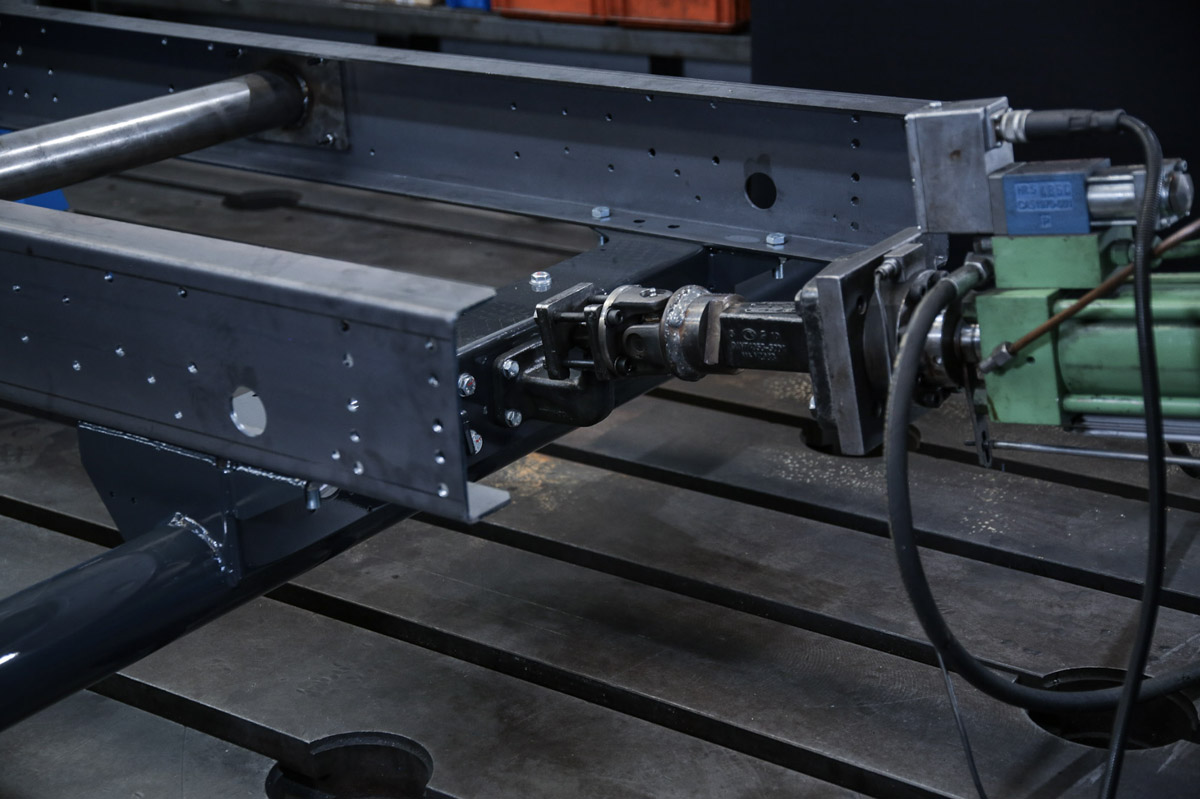

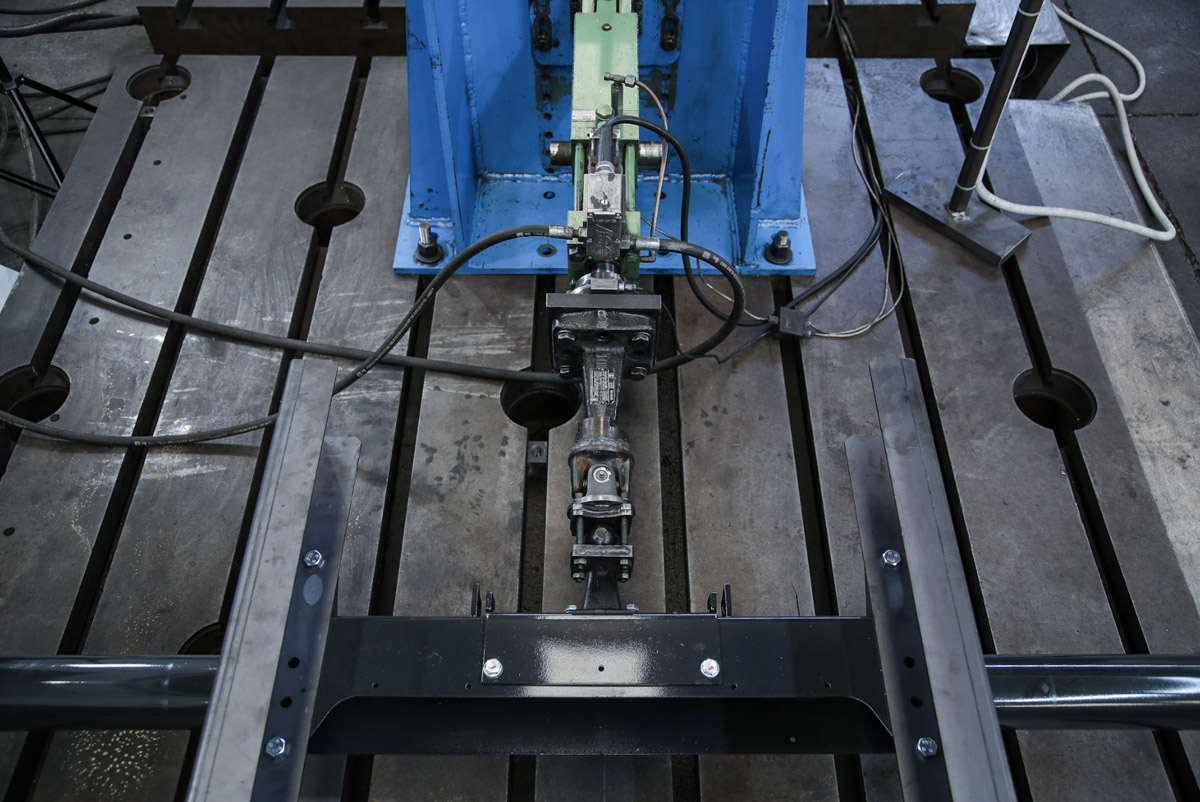

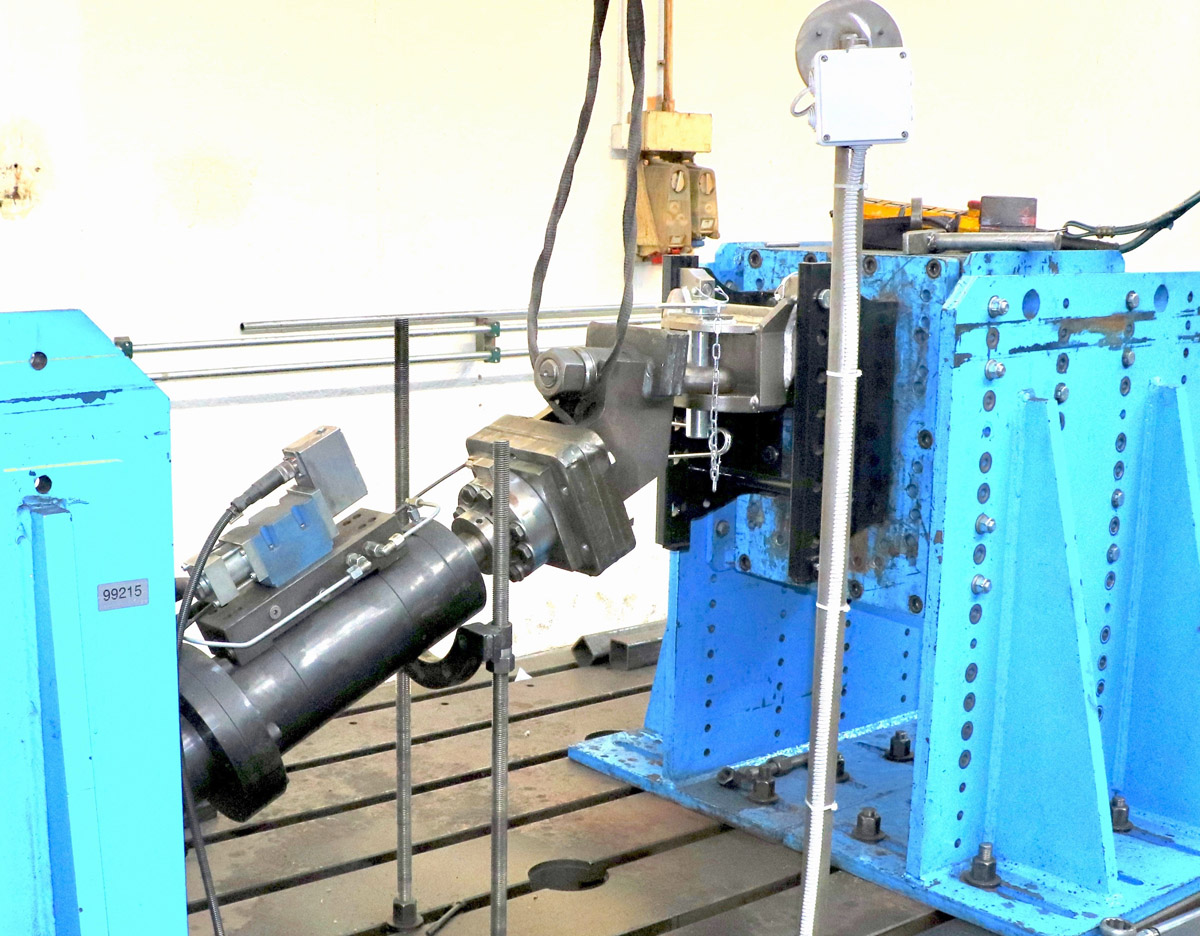

In both agricultural and industrial towing systems, each different vehicle (tractor, van, pick-up…) requires specific design and development with consequent structural adaptations and related Approvals.

The ability to collaborate in co-design with the customer is therefore a fundamental skill for our technicians.