Metalsecure has a team dedicated to feasibility analyzes and the development of the most effective and efficient processes and technologies to create the product as defined in the Customer’s specifications and/or envisaged in the Approvals obtained. Traceability and production flexibility are pursued by integrating both internal and external activities and processes through the selection of suppliers qualified to meet the required standards.

Production Technologies

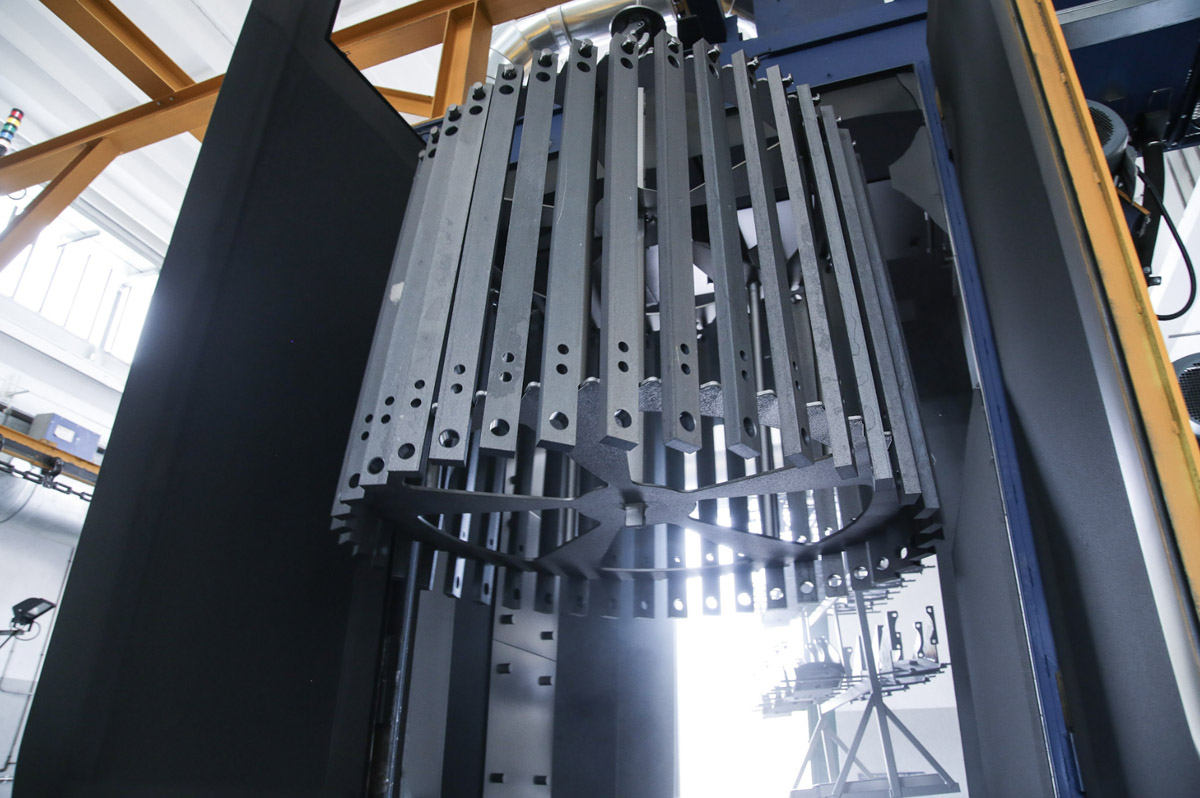

An integrated system that guarantees complete traceability of the process and maximum flexibility in production

We exclusively use flat sheet laser cutting centers and computer-controlled tube laser cutting centers that perform the dimensional specifications set out in the 3D drawings developed and controlled by our Engineering.

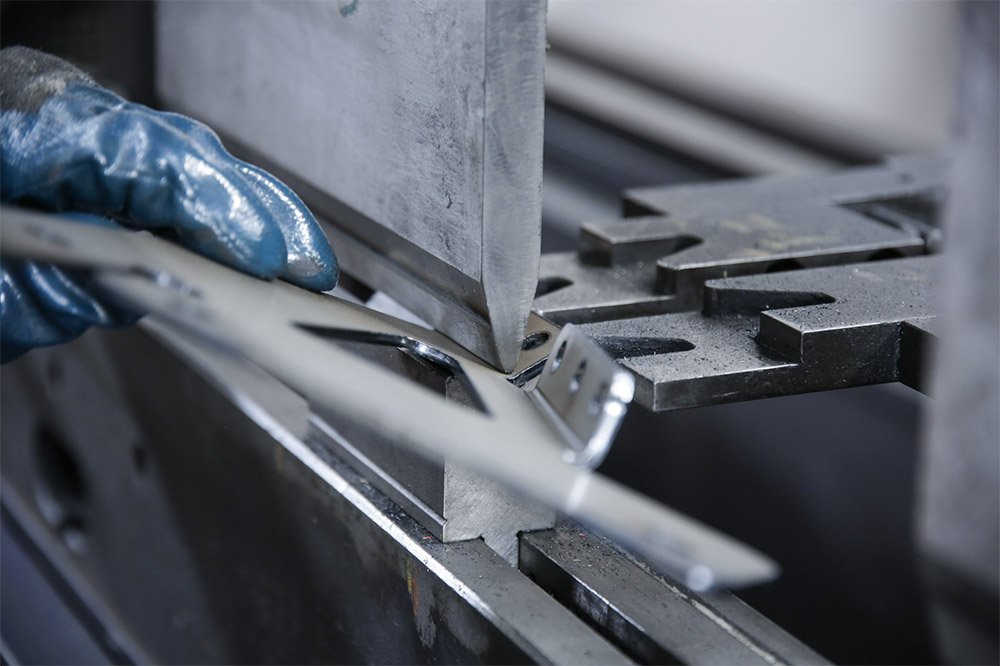

Sheet metal pieces and cut pipes are bent on the most modern bending presses always according to the calculations deriving from the 3D drawings. Tolerances and precision of the folds are controlled by our Quality system using arms with contact probes and laser scanning.

A range of presses up to 1000 tons. has always been available for specific projects whose equipment is developed and maintained internally.

Metalsecure has decades of experience in the production of poly-V pulleys by cold deformation of sheet metal obtained with specific fluoforming systems.

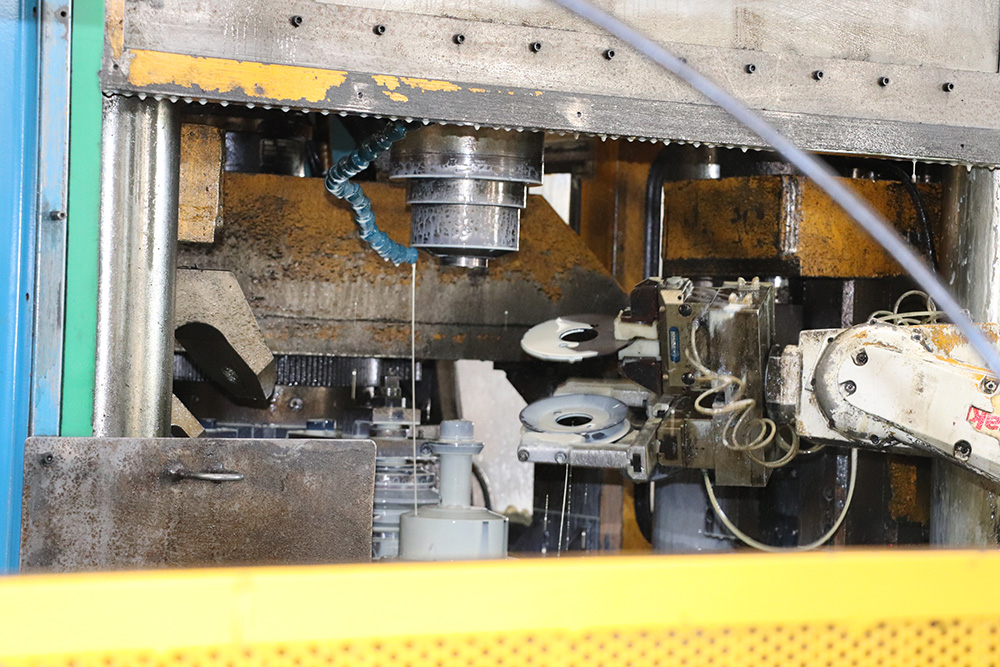

They are the heart of the production process in towing systems, especially on manual and automatic couplings, flanged sliders and sliding frames. Several vertical and horizontal CNC machining centers and with automatic pallet changer, always controlled by CAM computers, perform high-precision machining sequences that guarantee quality and tolerances as per agreed specifications.

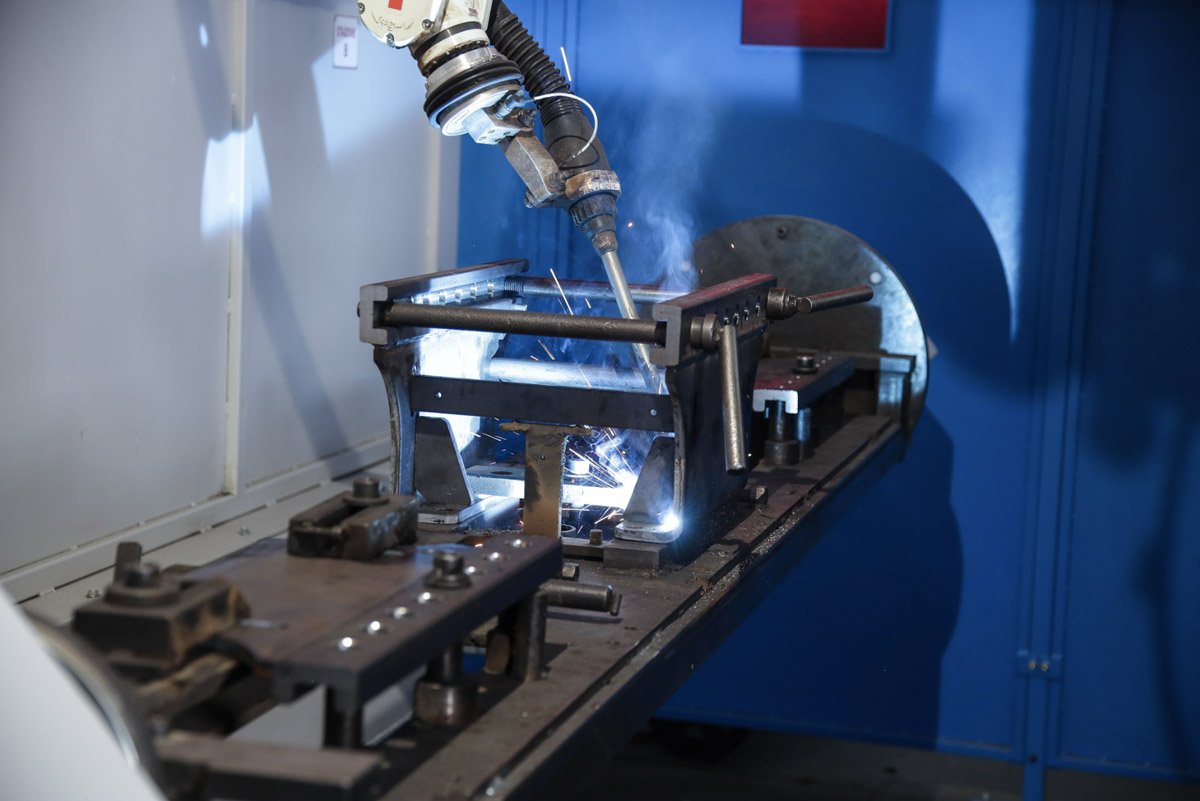

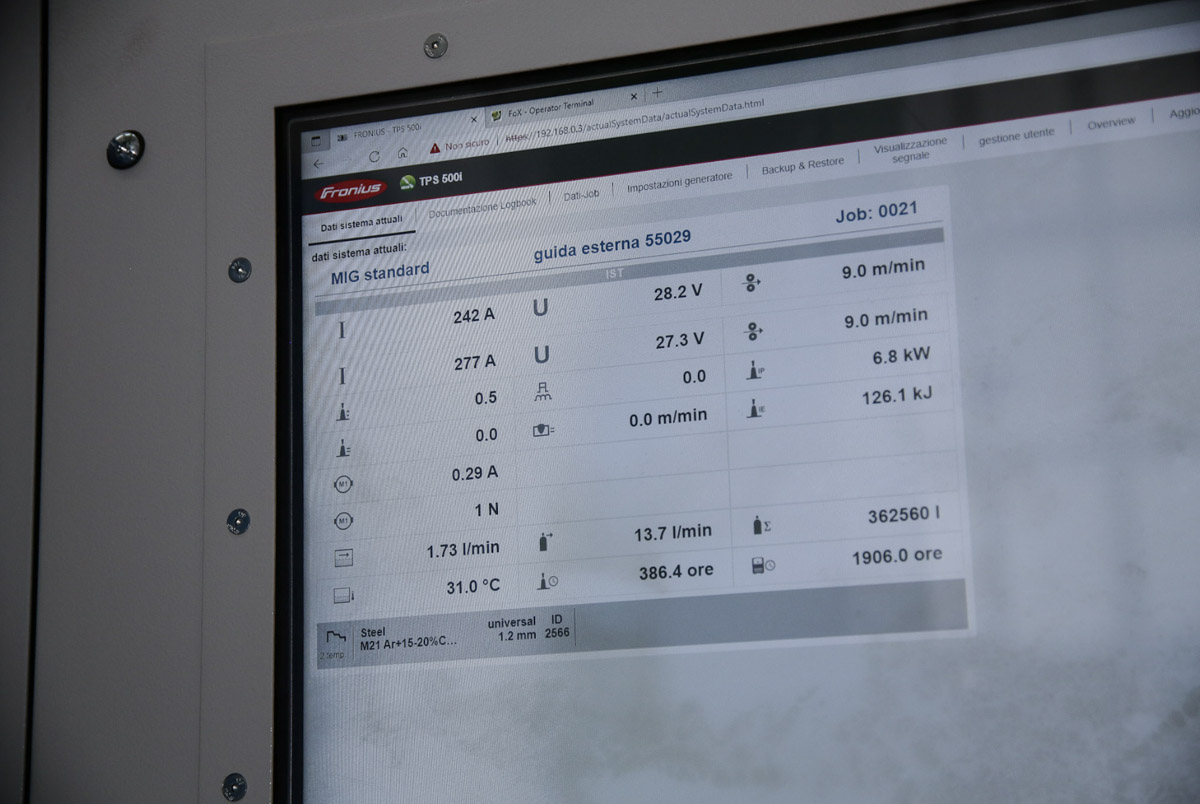

The welding process constitutes a further critical phase for the quality and performance of the towing systems. Entrusted exclusively to latest generation robots with continuous tracking of welding execution data, it uses jigs and production equipment made internally to guarantee full safety standards.

Metalsecure guarantees a complete cycle of surface treatments through the integration of internal and external processes traced and verified by its Quality service. Each metal component of production undergoes a complete sandblasting cycle to then be subjected to the most diverse sequences of treatments as required by the specifications of the individual customer. Galvanizing, phosphating, cataphoresis, powder coating and enamel painting are the most commonly managed application standards in order to ensure the best possible protection against rust and wear.

The various sub-components are assembled and tested with specific assembly equipment by qualified personnel and on dedicated benches. Each finished product is subjected to its own control cycle which certifies its compliance with the standards required by customers and approvals.

The strengthened internal logistic process and the new management information system allow a punctual delivery service to customers and an effective flow of materials and data aimed at guaranteeing the traceability of the components and the related processing phases.